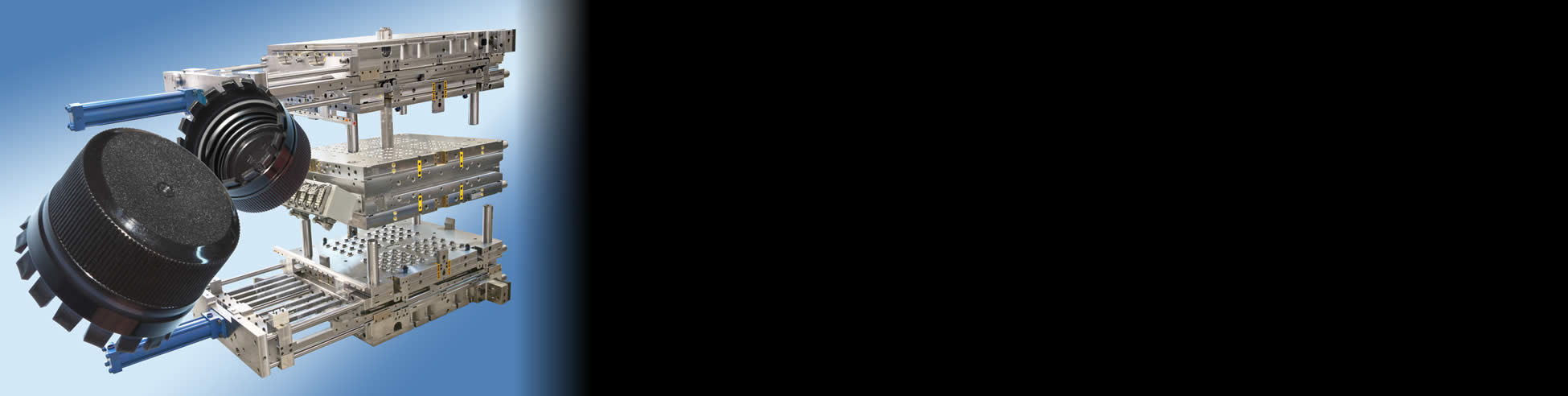

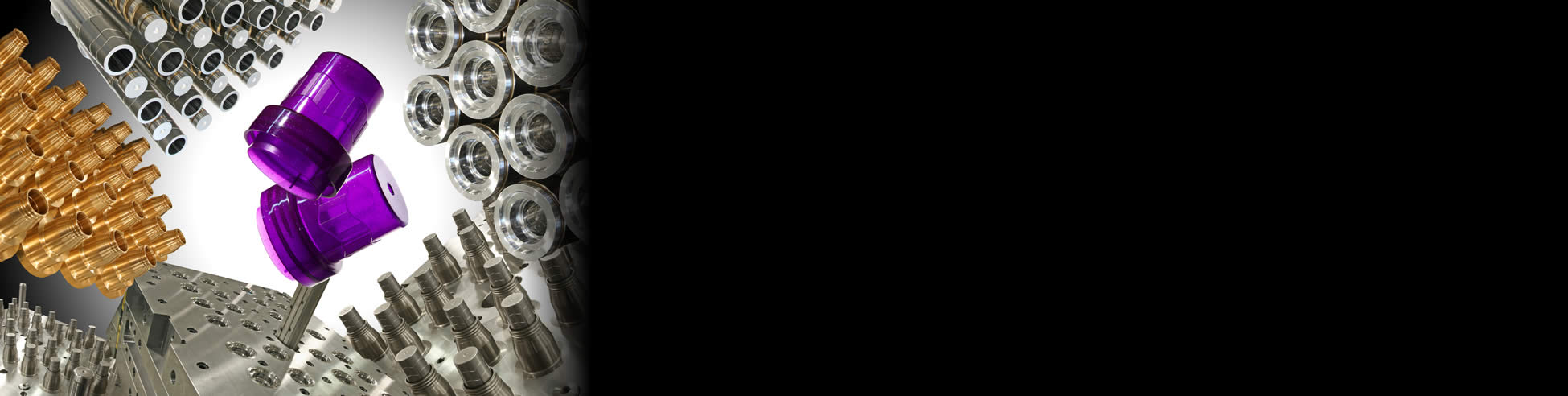

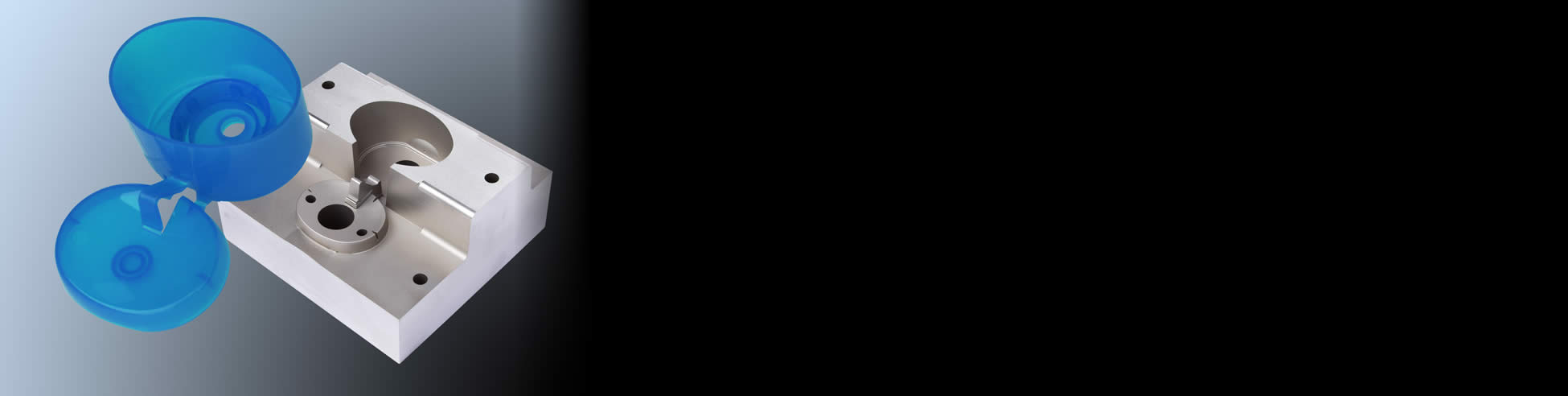

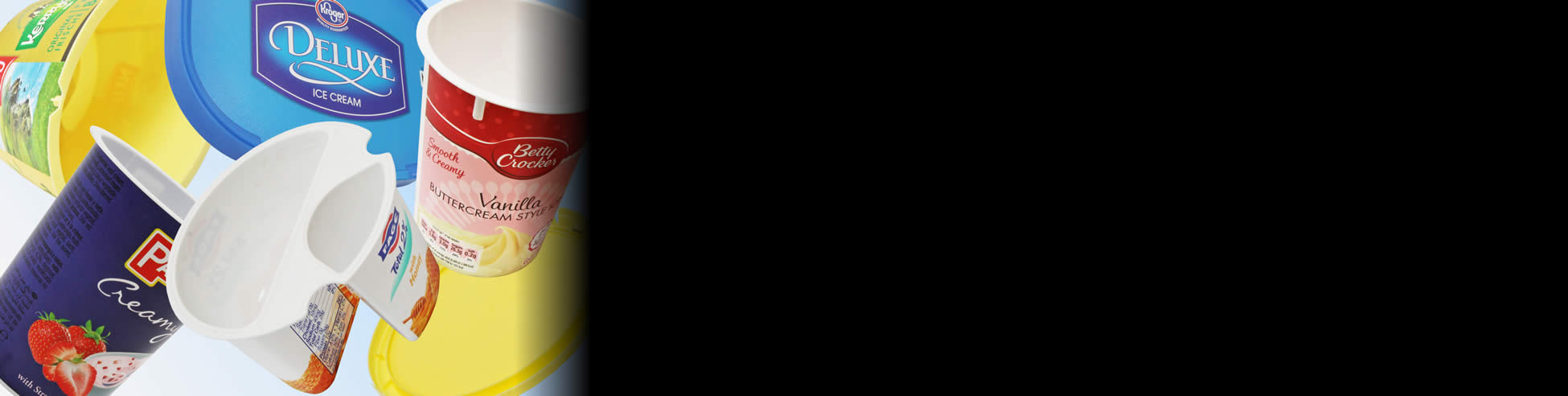

Pelco Tool and Mold prides itself in building high quality precision injection molds. With a dedicated team of 35 employees, we are large enough to handle high cavitation plastic injection molds for a variety of industries, yet small enough to provide a personal touch and quick reaction time. Our in house injection mold designers can help you develop that new part and create a mold that will provide great cycle time and last for millions of cycles. We can also work with a mold design that is ready for manufacturing. In any case, Pelco Tool would like to be part of your success.

Explore our website based on the industry you support or delve into our injection mold technologies to find out more specific details on how Pelco can make your next precision injection mold a highly productive one.

Located in the Chicagoland area, we are easily accessible by car from the Midwest and only 25 minutes from O’Hare Airport for air travel. We look forward to the opportunity to have you tour our facility. Please contact us at 630-871-1010 to schedule your visit.